|

BBCeng.info

Recollections of BBC engineering from 1922 to 1997 |

The British Broadcasting Corporation web site is: www.bbc.co.uk |

Transmitter Projects - Reminiscences

Sandale antenna system

By Tony Smith

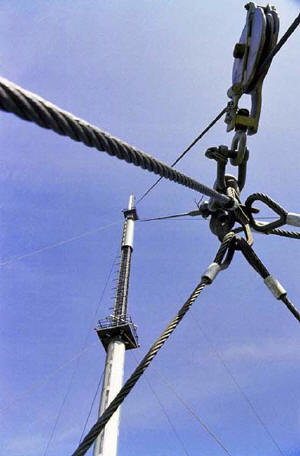

This gives a bit of an insight as to what went on during an installation. Back in the late 1970`s it was decided to give the Lakeland Fells a bit more colour by improving BBC Sandale`s transmitting capability. Architectural and Civil Engineering Department designed, manufactured and had installed a new antenna spine onto the top of the Sandale Mast. Then Transmitter Capital Projects Department loaded up their installation equipment and winch and set off from Brookmans Park to install the Antennas and feeders. (Click pictures to enlarge.)

The mast already rigged and the first UHF panels being lifted up and

installed.

Looking down from the platform at the cage coming up loaded with UHF panels.

The other is the view from the cage as it runs up the pilot bond.

The winch has to sited if possible so that the winch driver can always see

both upper and lower end of the winch bond without having to stare into the

sun.

These show the installation of the UHF panels onto the spine back in the

days when you could climb around on the steelwork as if you knew what you

were doing.

One morning we awoke to find that the fells had supplied some real Sandale

weather. We felt the need to go up to site to check that everything was safe

until the snow melt came.

After a rapid thaw set in the antenna test equipment came up in the cage and

T.C.P.D. Engineer Adrian Hartley is shown on the top platform crouched over

his delicate dials.

During the whole installation we had made great friends with the RAF.

Although they had been warned that personnel were working on the Mast they

seemed to want to take a closer look. One day as I was lounging on the top

platform holding a piece of some sort of test gear for Adrian I heard them

coming. I only just had time to pull out the trusty Olympus when this

Buccaneer came roaring past. As the camera only had its 35mm lens on you can

see he was fairly close.

Two days later I missed the chance of a lifetime when standing by the winch

as it was lifting some equipment I turned to the winch driver and remarked

on how rough the engine sounded. The next second the sky went dark and a

Vulcan bomber slowly lifted itself up over the mast top billowing black

smoke.

To us on the ground it seemed a great sight but it got the lads on the top

of the mast very excited as they had been about 700ft closer to it than us!

These show the delivery of the UHF feeders and the start of the most taxing

time of any installation. Although they look big and strong these Co-ax

cables have to be looked after like newly born babies. They are prone to all

manner of horrors but mainly getting dented and the engineers simply do not

like this. Also they need a lifting stocking about every 30metres on a

vertical lift which meant stopping at regular intervals to have them

installed. Another precaution that needs to be taken is to wrap and tape

rags and sackcloth over every sharp edge that the feeder could come into

contact with.

Feeder installation also needs more manpower as it takes two or three men to

operate the cable drum so that the cable comes off loosely and is not pulled

off by the winch. (If the cable is allowed to be pulled off by the winch

then you can end up with 1 5/8" cable instead of 4", which is certain to get

you off of the Engineers Christmas card list)

These photographs show the feeder being guided and fed into the base of the

Sandale mast as it is being lifted.

The chap at the top has to make sure that the feeder and the top connector

are straight with the antenna connectors before connecting up. Once this is

done and the cable is connected then the cable can be clamped in down the

mast.

Then suddenly the feeders have been cut on the ground, equalised and

installed into the building and before you know it T.C.P.D Engineer Adrian

Hartley is climbing up to remove some old test leads and check over the

system.

Adrian then stands on the top and declares it all fit for purpose so that we

can de-rig and go home.